Optimizing Warehouses with Lean Manufacturing Principles

June 4, 2025Modern warehouses face an array of complex challenges, from escalating operational costs and the relentless pressure for faster deliveries to the persistent issues of inventory accuracy and efficient space utilization. In today's dynamic global marketplace, the ability to streamline operations and enhance efficiency is no longer a luxury but a fundamental requirement for sustained success.

This is where lean manufacturing, a philosophy honed over decades in industrial settings, offers powerful solutions for warehouse environments.

Design Systems, Inc. stands as a premier engineering consulting firm, founded in 1983 in Farmington Hills, Michigan, with a rich history of delivering robust industrial engineering solutions, comprehensive engineering services, and expert program management. With a team of over 250 dedicated professionals spanning three countries, we bring unparalleled experience to the table, helping organizations navigate and conquer their most pressing operational hurdles.

This article will explore how applying lean manufacturing principles can fundamentally transform your warehouse operations, driving efficiency and strengthening your bottom line.

Understanding Lean Manufacturing Fundamentals in a Warehouse Context

At its core, lean manufacturing is about maximizing value for the customer while systematically eliminating waste. In a warehouse, waste manifests in various forms. Think of unnecessary transportation of goods, excessive inventory holding, inefficient motion by personnel, products waiting for processing, over-processing tasks, or defects in order fulfillment.

The lean philosophy provides a structured approach to identify these inefficiencies and implement continuous improvements.

Key principles of lean, directly applicable to warehousing, include:

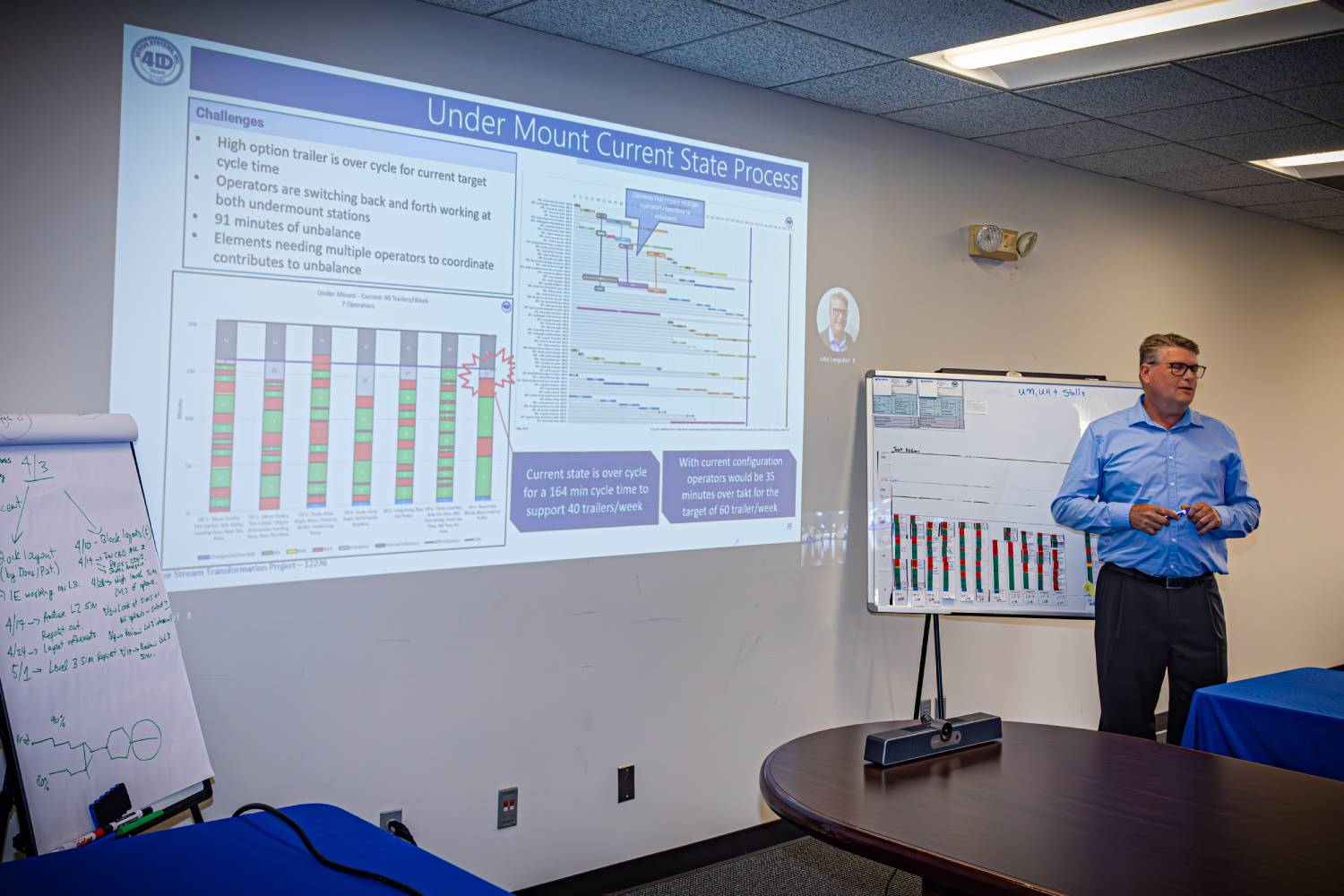

Value Stream Mapping: Visualizing the entire flow of materials and information to identify non-value-adding steps.

Pull Systems: Producing or moving goods only when needed, as opposed to pushing them through the system based on forecasts.

Standardized Work: Establishing clear, consistent procedures for all tasks to reduce variation and errors.

Continuous Improvement (Kaizen): Fostering a culture where everyone actively seeks opportunities for small, incremental enhancements.

Key Strategies for Lean Warehouse Optimization

Key Strategies for Lean Warehouse Optimization

Applying lean thinking to your warehouse involves a multi-faceted approach, targeting common pain points to unlock significant performance gains.

Streamlining Material Flow and Layout

An optimized warehouse layout is paramount for efficient operations. We focus on designing layouts that minimize travel distances, reduce congestion, and enhance the smooth flow of goods from receiving to shipping.

This includes strategic placement of high-demand items, logical sequencing of work zones, and clear pathways for equipment and personnel. Utilizing tools like value stream mapping allows us to analyze current material flow and pinpoint areas where motion and transportation waste can be significantly reduced.

Inventory Management and Control

Excess inventory ties up capital, consumes valuable space, and increases the risk of obsolescence or damage. Lean strategies advocate for precise inventory management, moving towards a just-in-time approach where materials and products are received and moved only when required. This involves robust tracking systems, accurate demand forecasting, and disciplined inventory reduction programs to free up resources and enhance responsiveness.

Process Improvement and Standardization

Consistency is a cornerstone of Lean. Developing clear standard operating procedures for every task, from receiving and putaway to picking and packing, ensures that work is performed efficiently and safely every time. Furthermore, cultivating a culture of continuous improvement, often through methodologies like Kaizen, empowers your team to identify and solve problems at their source, leading to ongoing enhancements in productivity and quality.

Integrating Smart Technologies for Enhanced Lean Operations

The principles of Industry 4.0 offer powerful tools to amplify lean efforts in the warehouse. Design Systems, Inc. leverages advanced technologies to provide unprecedented visibility and control. Our initiatives include:

Laser Scanning: Creating highly accurate digital twins of your warehouse for precise layout planning and optimization.

3D Model Development: Designing and visualizing improved layouts and material handling systems before physical implementation, ensuring optimal flow.

Virtual Commissioning: Simulating processes and systems in a virtual environment to identify and resolve potential issues before they impact live operations, significantly reducing costly errors and delays.

These technologies enable data-driven decision-making, automate repetitive tasks, and further refine processes, leading to a truly smart and efficient warehouse.

The Benefits of Lean Manufacturing for Your Warehouse

The Benefits of Lean Manufacturing for Your Warehouse

The advantages of adopting lean manufacturing principles in your warehouse are substantial and far-reaching:

Reduced Operational Costs: By eliminating waste in all its forms, you save on labor, space, inventory holding, and energy.

Improved Inventory Accuracy: Streamlined processes and better control lead to fewer discrepancies and more reliable stock counts.

Enhanced Productivity and Throughput: Optimized layouts and efficient workflows mean more goods processed in less time.

Better Space Utilization: Less waste and smarter storage strategies allow you to make the most of your existing footprint.

Increased Customer Satisfaction: Faster, more accurate order fulfillment leads directly to happier customers and stronger business relationships.

Partner with an Expert Lean Manufacturing Consultant Like Design Systems, Inc.

Achieving comprehensive warehouse optimization through lean manufacturing requires specialized knowledge and practical experience.

Design Systems, Inc. brings over four decades of expertise to every project. Our origins in 1983 as industrial engineering consultants mean lean principles are woven into the very fabric of our approach. With a global team of over 250 seasoned professionals, we have successfully partnered with diverse clients across manufacturing, parcel handling, and warehousing sectors.

Our commitment to delivering top-notch engineering and industrial design solutions is evidenced by our extensive experience and numerous industry accolades. We do not offer one-size-fits-all solutions; instead, we work closely with you to understand your unique operational challenges and tailor a lean strategy that precisely addresses your needs.

Whether it is improving your existing warehouse efficiency, designing a cutting-edge smart factory, or integrating advanced Industry 4.0 technologies, we have the proven capability to help you achieve manufacturing excellence and a stronger bottom line.

Building a Future-Ready, Efficient Warehouse

Embracing lean manufacturing for warehouse optimization is a strategic investment that yields tangible results in efficiency, cost reduction, and competitive advantage. It transforms your warehouse from a cost center into a powerful asset that supports your overall business goals.

Ready to unlock the full potential of your warehouse operations? Contact Design Systems, Inc. today to discuss your specific needs and learn how our lean manufacturing consultants can guide you toward a more efficient and profitable future.

Visit our website to explore our comprehensive range of services and see how we can help you build a future-ready, optimized warehouse.