Closing the Skills Gap: How Digital Twin + VR Simulation are Building the Manufacturing Workforce

May 8, 2025Over 2.1 million manufacturing jobs in the U.S. could go unfilled by 2030. Why? Because today's workforce isn't trained for tomorrow's factories.The manufacturing sector faces a critical challenge: equipping its workforce with the advanced skills demanded by Industry 4.0. Traditional training methods often fall short in preparing technicians for increasingly complex systems and processes.

Design Systems, Inc.(DSI), a Farmington Hills, Michigan-based engineering consulting firm established in 1983, offers a powerful solution. For decades, we've provided cutting-edge engineering consulting and industrial design solutions. Today, we explore how the powerful combination of digital twin technology and virtual reality (VR) with simulations embedded offers a transformative approach to bridging this gap, empowering the manufacturing workforce for the era of Industry 4.0.

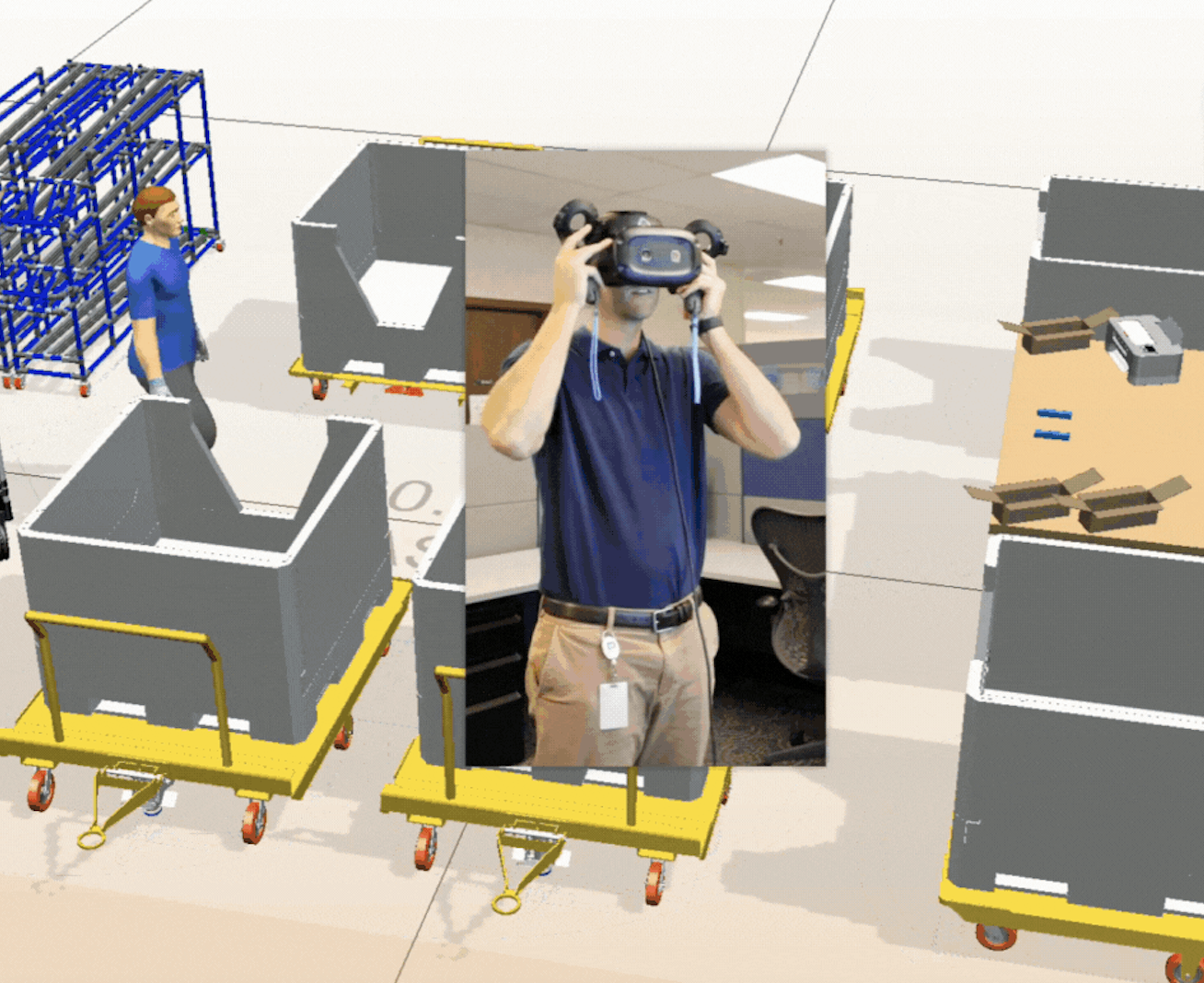

By integrating the precision of digital twins and computer simulations with the immersive capabilities of VR, we create realistic training environments that accelerate learning, reduce errors, and develop the manufacturing workforce of tomorrow.

Understanding the Evolving Manufacturing Landscape and the Skills Challenge

The manufacturing sector is undergoing a rapid evolution, propelled by the advancements of Industry 4.0. Automation, robotics, and interconnected systems are becoming increasingly prevalent. This technological leap necessitates a workforce possessing new and specialized skills.

Traditional training methods often struggle to keep pace with this rapid change.

On-the-job training can disrupt production schedules and raise safety concerns.

Physical training environments can be time-consuming and costly.

Materials to support training often have high overhead costs.

The need for innovative and engaging solutions that can effectively equip workers with the skills required for these advanced technologies is paramount.

The Power of the Digital Twin in Manufacturing

At the heart of this innovative approach lies the digital twin: a dynamic virtual representation of physical assets, processes, and entire systems within a manufacturing environment.

DSI's deep expertise in engineering services and 3D model development forms the bedrock for creating precise and comprehensive digital twins. These virtual replicas extend beyond mere visualization; they offer a wealth of data and insights, allowing for:

Process optimization

Predictive maintenance

Virtual commissioning

This rich data foundation makes the digital twin an ideal starting point for creating highly realistic and effective training simulations.

Immersive Learning Through VR: A Practical Approach

Stepping into a manufacturing environment through VR & simulation offers a transformative learning experience. This technology creates immersive and interactive scenarios that allow trainees to engage with equipment and processes in a completely new way.

DSI’s simulation service harnesses the data and fidelity of the digital twin to construct these realistic virtual worlds. The advantages for manufacturing training are significant:

Safe and Risk-Free Learning: Trainees can practice complex or potentially hazardous tasks without real-world consequences.

Accelerated Skill Acquisition: Immersive experiences enhance engagement and retention, leading to faster learning curves.

Reduced Errors and Improved Quality: Practice in a simulated setting allows for identification and correction of mistakes before they occur in actual production.

Cost-Effectiveness: Reduced downtime, material waste, and travel expenses associated with traditional training.

Standardized Training: Consistent and repeatable training modules ensure all employees receive the same level of instruction.

Performance Tracking and Feedback: VR simulations can track trainee progress and provide personalized feedback for improvement.

The Synergy: Digital Twin and VR Simulation in Action

The Synergy: Digital Twin and VR Simulation in Action

The true power emerges when the digital twin and VR simulation work in concert. Imagine:

New technicians learn the intricacies of a complex machine by interacting with its virtual counterpart, guided by the precise data and behavior mirrored from the digital twin.

Assembly line workers practicing optimized workflows in a virtual simulation before ever stepping onto the actual production floor.

Emergency response teams honing their protocols in a realistic virtual environment, preparing them for critical situations without any real-world risk.

Design Systems, Inc. utilizes its laser scanning and 3D model development capabilities to create highly accurate virtual representations of existing facilities, further enhancing the realism of the training scenarios.

The accuracy of the digital twin is crucial; it ensures that the virtual experience faithfully replicates the real-world environment, leading to more effective and transferable skills. Industry 4.0 initiatives and the integration of advanced technologies further enhance the sophistication and effectiveness of both digital twins and VR training modules.

Practical Applications and Benefits for Diverse Manufacturing Markets

Design Systems, Inc.'s VR simulation training solutions offer tangible benefits across the diverse manufacturing markets we serve:

Manufacturing: Training on specific production processes, equipment operation, and stringent quality control procedures.

Parcel Handling: Simulating sorting processes, teaching conveyor system maintenance, and reinforcing critical safety protocols.

Warehousing: Training on warehouse management systems, the safe operation of material handling equipment, and efficient inventory management strategies.

The adaptability of this approach allows us to tailor solutions to the specific needs and challenges of each industry, delivering targeted and impactful training outcomes.

See Our VR Simulation in Action

See Our VR Simulation in Action

To see how Design Systems, Inc. leverages process simulation software and industrial engineering expertise integrated with VR technology, watch our demonstration video: DSI VR Simulation Demo.

As the video illustrates, we can create a digital twin of a work cell and drive significant optimization and efficiency improvements. For example, the video demonstrates how cycle time was reduced from 117 seconds to 80 seconds, a 30% improvement, through the application of these technologies [03:05]. Our services extend to product assembly sequencing, cycle time validation, and ergonomic and safety assessments [03:18].

Design Systems, Inc.: Your Partner in Workforce Transformation

Design Systems, Inc. brings decades of experience and a deep understanding of the manufacturing landscape to every partnership. Founded in 1983, our commitment to providing exceptional engineering and industrial design solutions remains unwavering. Our team of over 250 professionals across three countries brings a wealth of knowledge in:

Lean Manufacturing

Supply chain services

Project management

Digital engineering services

Advanced technologies

Our numerous awards and extensive track record speak to our dedication to delivering excellence. We are more than just consultants; we are your strategic partners in workforce transformation, helping you navigate the complexities of modern manufacturing and equip your team for success.

Conclusion: Preparing Tomorrow’s Manufacturing Technicians Today

As the cost of untrained labor rises and operational downtime becomes more expensive, companies must rethink how they equip their teams. The integration of digital twins and VR simulation represents a significant leap forward in manufacturing training. It offers a powerful and effective way to address the growing manufacturing skills gap, enhance workforce capabilities, and prepare for the future of manufacturing. By creating immersive, realistic, and risk-free learning environments, these technologies accelerate skill acquisition, reduce errors, and ultimately empower skilled technicians.

Design Systems, Inc. is at the forefront of this innovation, ready to help your organization leverage the power of digital twins and VR simulation to build a more skilled, efficient, and future-ready workforce.

Contact us today to explore how we can help you transform your training initiatives.